Browse from the range of our products

Pressure Gauge | Temperature Gauge | Sensor | Associated Auxillaries

Utility Pressure / Differential Pressure Gauges

1. 131B Utility Pressure Gauge, Bourdon

| Dial Size: | 1 1/2″, 2″, 2 1/2″, 4″, 6″ |

| Accuracy: | ±2.5% of full scale for 1 1/2″, 2″ ±1.6% of full scale for 2 1/2″, 4″, 6″ |

| Wetted Parts: | Copper Alloy |

| Enclosure: | SS304, Crimped Bezel, IP 65 |

| Mounting: | Bottom, Center Back, Eccentric Back |

| Mounting Accessories: | Back Flange, Front Flange, Panel Mounting Clamp |

| Standard Options: | Glycerin Filling, SS tag plate, Restriction screw, Refrigerant Scales, Color band, Private labelling |

2. 131C Utility Pressure Gauge, Capsule

| Dial size: | 1½”, 2″, 2½”, 4″, 6″ |

| Accuracy: | ±1.6% for 2½”, 4″, 6″ |

| Wetted parts: | Copper Alloy |

| Enclosure: | SS 304, Bayonet bezel, IP 54 |

| Mounting: | Bottom, Centre Back, Eccentric back |

| Mounting accessories: | Back Flange, Front Flange, Panel mounting clamp |

| Standard options: | Glycerin filling, SS Tag Plate Restriction Screw |

3. 133B / 134B Process Pressure Gauge, Bourdon

| Dial size: | 1½”, 2″, 2½”, 4″ |

| Accuracy: | ±2.5% for 1½”, 2″ ±1.6% for 2½”, 4″ |

| Wetted parts: | SS 316L / MONEL* |

| Enclosure: | SS 304, Crimped bezel, IP65 |

| Mounting: | Bottom, Centre Back |

| Mounting accessories: | Back Flange, Front Flange, Panel mounting clamp |

| Standard options: | Glycerin filling, SS Glycerin Filling, Restriction Screw Tag Plate , Restriction Screw Oxygen Service, Ammonia Scale, Color band, Private Labelling |

4.332P / 333P Utility Differential Pressure Gauge, Piston

| Dial size: | 2½”, 4″, 4½”, 6″ |

| Accuracy: | ±1.6% for full scale |

| Wetted parts: | SS 316 / SS 316L |

| Enclosure: | SS 304, Push-fit bezel, IP 67 |

| Mounting: | Bottom, Back, In-line |

| Mounting accessories: | Front flange, 2″ Stanchion |

| Standard options: | SS Tag Plate, Oxygen Service Maximum Reading Pointer Color band, Private Labelling |

Process Pressure / Differential Pressure Gauges

1. 233B / 234B Process Pressure Gauge, Bourdon

| Dial size: | 4″, 6″, 8″, 10″ |

| Accuracy: | ±1.0% for full scale |

| Wetted parts: | SS 316LAlloy / MONEL / Hastelloy C |

| Enclosure: | SS 304, Bayonet bezel, IP 68 |

| Mounting: | Bottom, Centre Back, Eccentric back |

| Mounting accessories: | Back Flange, Front Flange,Panel mounting clamp, 2″ Stanchion |

| Standard options: | Glycerin Filling, SS Tag Plate Restriction Screw, Oxygen Service External Zero Adjustment Color bands, Private Labelling |

2. 253B / 254B Solid Front Pressure Gauge, Bourdon

| Dial size: | 4″ & 6″ |

| Accuracy: | ±1.0% of full scale / ±0.5% (optional) |

| Wetted parts: | SS 316L / MONEL / Hastelloy C |

| Enclosure: | SS 304, Bayonet bezel, IP 67 |

| Mounting: | Bottom |

| Mounting accessories: | Back Flange, 2″ Stanchion |

| Standard Options: | Glycerin Filling, Restriction Screw SS Tag Plate, External Zero Adjustment 150% Over Pressure Protection Color bands, Private Labelling |

3. 273B / 274B Phenolic Case Pressure Gauge, Bourdon

| Dial size: | 4½” |

| Accuracy: | ±0.5% of full scale / ±1.0% (optional) |

| Wetted parts: | SS 316L / MONEL* |

| Enclosure: | Polypropylene, Screwed bezel, IP 67 |

| Mounting: | Bottom, Eccentric Back |

| Mounting accessories: | Back Flange |

| Standard options: | Glycerin filling, SS Tag Plate Restriction Screw, Oxygen Service Phenolic Resin case & ring Color bands, Private Labelling |

4. 433W Differential Pressure Gauge, Bellows

| Dial size: | 6″ |

| Accuracy: | ±1.0% of full scale |

| Wetted parts: | SS 316L |

| Enclosure: | SS 304, Bayonet bezel, IP 67 |

| Mounting: | Bottom |

| Mounting accessories: | Back Flange, 2″ Stanchion |

| Standard options: | Glycerin Filling, SS Tag Plate, Max. Reading Pointer Electric contacts, Flow Measuring Scale Color band, Private Labelling. |

Temperature Gauges

1. 533M Standard Temperature Gauge, Bimetal

| Dial size: | 2½”, 4″ & 6″ |

| Accuracy: | Class 1 / ±1.0% of full scale |

| Sensor Details: | SS 316 Ø6 / Ø8 / Ø9.5 / Ø10 / Ø12 65mm up to 750mm |

| Enclosure: | SS 304, Bayonet bezel, IP 68 |

| Mounting: | Bottom, Centre Back |

| Mounting accessories: | Front Flange |

| Standard options: | SS Tag Plate, Color bands, Private Labelling |

2. 553M Process Temperature Gauge, Bimetal

| Dial size: | 3″, 4″, 4½”, 6″ |

| Accuracy: | 1 / ±1.0% of full scale |

| Sensor Details: | SS 316 Ø6 / Ø8 / Ø9.5 / Ø10 / Ø12 65mm up to 750mm |

| Enclosure: | SS 304, Bayonet bezel, IP 67 |

| Mounting: | Every Angle |

| Standard options: | SS Tag Plate, Restriction Screw External Zero Adjustment Glycerine / Silicon Oil Filled Color bands, Private labelling |

3. 533G Temperature Gauge, Gas-filled

| Dial size: | 4″ & 6″ |

| Accuracy: | ±1.6% of full scale |

| Sensor Details: | SS 316 Ø6 / Ø8 / Ø9.5 / Ø10 / Ø12 65mm up to 750mm |

| Remote Mounting Details: | SS 316L 1000 mm up to 10000mm |

| Armour: | SS 304, SS 316, PVC coated |

| Enclosure: | SS 304, Bayonet bezel, IP 65 |

| Mounting: | Back Flange, Front Flange, Panel mounting clamp, 2″ Stanchion |

| Standard options: | Glycerin filling, SS Tag Plate Electric contacts, Max. Reading Pointer External Zero Adjustment Color bands, Private Labelling |

Pressure/Differential Pressure Gauges

1. 232C Process Pressure Gauge, Capsule

| Dial size: | 2½”, 4″ & 6″ |

| Accuracy: | ±1.6 of full scale |

| Wetted parts: | SS 316 capsule + SS 316L socket |

| Enclosure: | SS 304, Bayonet bezel, IP 68 |

| Mounting: | Bottom, Centre Back, Eccentric back |

| Mounting accessories: | Back Flange, Front Flange, Panel mounting clamp Panel mounting clamp, 2″ Stanchion |

| Standard options: | SS Tag Plate, Restriction Screw Internal Zero Adjustment Color bands, Private Labelling |

2. 233D / 234D / 235D Process Pressure Gauge, Diaphragm

| Dial size: | 4″ & 6″ |

| Accuracy: | ±1.0% of full scale / ±0.5% (optional) |

| Wetted parts: | SS 316L / MONEL / Hastelloy C |

| Enclosure: | SS 304, Bayonet bezel, IP 67 |

| Mounting: | Bottom |

| Mounting accessories: | Back Flange, 2″ Stanchion |

| Standard options: | SS Tag Plate, Restriction Screw 150% Over Pressure Protection Color bands, Private labelling |

3. 432D Differential Pressure Gauge, Single Diaphragm

| Dial size: | 4″ & 6″ |

| Accuracy: | ±2.5% of full scale |

| Wetted parts: | SS 316 / SS 316L |

| Enclosure: | SS 304, Bayonet bezel, IP 65 |

| Mounting: | Bottom, Back |

| Mounting accessories: | Back Flange, Front Flange, 2″ Stanchion |

| Standard options: | Glycerin Filling, SS TTag Plate, Max. Reading Pointer Electric contacts, Flow Measuring Scale Color band, Private Labelling |

4. 433D / 434D / 435D Differential Pressure Gauge, Double Diaphragm

| Dial size: | 4″ & 6″ |

| Accuracy: | ±1.6% of full scale |

| Wetted parts: | SS 316L / MONEL / Hastelloy C |

| Enclosure: | SS 304, Bayonet bezel, IP 65 |

| Mounting: | Bottom, Centre Back |

| Mounting accessories: | Back Flange, Front Flange, 2″ Stanchion |

| Standard options: | Glycerin Filling, SS TTag Plate, Max. Reading Pointer, Electric contacts, Flow Measuring Scale Color band, Private Labelling |

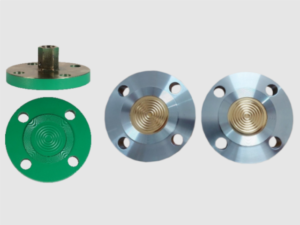

Chemical Seal Diaphragms

1. 611T / 621T / 631T Chemical seal diaphragms, Bolted

| Diaphragm: | SS 316L, Hastelloy C, Inconel, Monel Tantalum, Titanium, Super Duplex |

| Bottom Chamber: | SS 316L, Hastelloy C, Inconel, Monel Titanium, PVC, Polypropylene |

| Top Chamber: | SS 304, SS 316 |

| Process Connection: | ½” NPT(M) / ½” BSP(M) / M20 x 1.5P ⅜” NPT(M) / ½” NPT (F) / ¾” NPT (M) |

| Filling Liquid: | Silicon oils, Syltherm, Halo-carbon Food grade, Flurolube, etc. |

| Standard options: | Material Test Certificate Wetted parts tested to NACE standards |

2. 641T / 652T Chemical seal diaphragms, Welded

| Diaphragm: | SS 316L, Hastelloy C, Inconel, Monel Tantalum, Titanium, Super Duplex |

| Other wetted parts: | SS 316L, Hastelloy C, Inconel Monel, Titanium |

| Non-wetted parts: | SS 304, SS 316 |

| Process Connection: | ½” NPT(M) / ½” BSP(M) / M20 x 1.5P ⅜” NPT(M) / ½” NPT (F) |

| Filling Liquid: | Silicon oils, Syltherm, Halo-carbon Food grade, Flurolube, etc. |

| Standard options: | Material Test Certificate Wetted parts tested to NACE standard |

3. 641F / 661F Chemical seal diaphragms, Flanged Diaphragm

| Diaphragm: | SS 316L, Hastelloy C, Inconel, Monel Tantalum, Titanium, Super Duplex |

| Bottom Chamber: | SS 316L, Hastelloy C, Inconel, Monel Titanium, PVC, Polypropylene |

| Filling Liquid: | Silicon oils, Syltherm, Halo-carbon Food grade, Flurolube, etc. |

| Process Connection: | ANSI / API / ISO / EN flanged with Flat / Serrated / RTJ facing |

| Standard options: | Material Test Certificate Wetted parts tested to NACE standards, PFA lining / coating, Gold / Silver plating on diaphragm |

4. 642F / 672F Chemical seal diaphragms, Flanged

| Diaphragm: | SS 316L, Hastelloy C, Inconel, Monel Tantalum, Titanium, Super Duplex |

| Bottom Chamber: | SS 316L, Hastelloy C, Inconel, Monel Titanium, PVC, Polypropylene |

| Process Connection: | ANSI / API / ISO / EN flanged with Flat / Serrated / RTJ facing |

| Filling Liquid: | Silicon oils, Syltherm, Halo-carbon Food grade, Flurolube, etc. |

| Standard options: | Material Test Certificate, Wetted parts tested to NACE standards, PFA coating, Gold / Silver plating on diaphragm & RF |

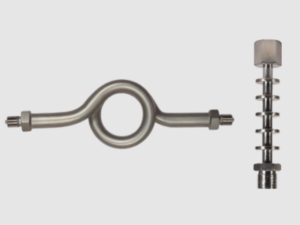

Accessories

1. 9111 / 9115 Siphon / Cooling Element

| Material of Construction : | SS 304, SS 316, SS 316L |

| Type of Construction: | Coil / Trumpet / U – type for siphon Fin type with various length |

| Connections: | ¼”, ⅜”, ½”, ¾” with Male / Female in NPT / BSP / G / R / PT threads ANSI / API / ISO / EN flanged with Flat / Serrated / RTJ facing |

| Max Working Temp. / Pressure: | 250°C / 400 bar Consult factory for compatibility |

| Standard options: | Material Test Certificate Wetted parts tested to NACE standards |

2. 9113 Pulsation Dampener

| Material of Construction : | SS 304, SS 316, SS 316L, Monel Hastelloy C, Inconel |

| Connections: | ¼”, ⅜”, ½”, ¾” with Male / Female in NPT / BSP / G / R / PT threads |

| Max Working Temp. / Pressure: | 250°C / 400 bar, Consult factory for compatibility |

| Standard options: | Material Test Certificate Wetted parts tested to NACE standards |

3. 9114 Overload Protector

| Material of Construction: | SS 304, SS 316, SS 316L, Monel Hastelloy C, Inconel Max |

| Working Temp. / Pressure: | 250°C / 400 bar Consult factory for compatibility |

| Connections: | ¼”, ⅜”, ½”, ¾” with Male / Female in NPT / BSP / G / R / PT threads |

| Standard options: | Material Test Certificate Wetted parts tested to NACE standards |

4. 9216 Flushing Ring

| Material of Construction: | SS 304, SS 316, SS 316L, Monel Hastelloy C, Inconel Max |

| Working Temp. / Pressure: | 250°C / 400 bar Consult factory for compatibility |

| Connections: | ANSI / API / ISO / EN flanged with Flat / Serrated / RTJ facing |

| Flushing Ports (Plugged) : | Single / Double ¼” NPT (F) / ½” NPT (F) |

| Standard options: | Material Test Certificate Wetted parts tested to NACE standards |

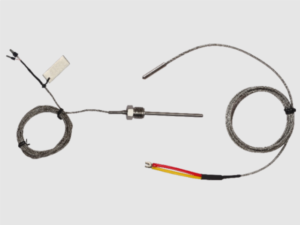

RTD / Thermocouple & Thermowells

1. 711R / 711E RTD / Thermocouple, Transition joint

| Element type: | RTD:- Pt-100, Pt-500, Pt-1000 Thermocouple: K, J, N, E, T Noble Thermocouple: R, S, B |

| Accuracy: | RTD:- Class A [IEC 751] Thermocouple: Class 2 [ANSI MC 96.1] |

| Sensor details: | SS 316 Ø6 / Ø8 / Ø9.5 / Ø10 / Ø12 25mm up to 25000mm |

| Termination: | Extension & Compensating cables PTFE/PTFE or PTFE/PTFE/SS braded Others on request |

| Standard options : | Head mount transmitter [4 – 20mA] Cable glands & Blind plugs |

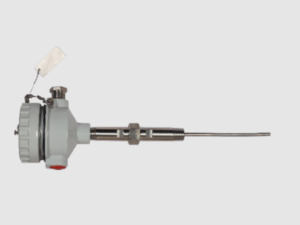

2. 722R / 732R / 742R / 722E / 732E / 742E RTD / Thermocouple, With Enclosure

| Element type: | RTD:- Pt-100, Pt-500, Pt-1000 Thermocouple: K, J, N, E, T Noble Thermocouple: R, S, B |

| Accuracy: | RTD:- Class A [IEC 751] Thermocouple: Class 2 [ANSI MC 96.1] |

| Sensor details: | SS 316 Ø6 / Ø8 / Ø9.5 / Ø10 / Ø12 25mm up to 25000mm |

| Termination : | Weatherproof / Flameproof Enclosure Ex-proof / ATEX approved Enclosure Others on request |

| Standard options : | Head mount transmitter [4 – 20mA] Cable glands & Blind plugs |

3. 752R / 762R / 752E / 762E RTD / Thermocouple, Nipple / NUN extension

| Element type: | RTD: – Pt-100, Pt-500, Pt-1000 Thermocouple: K, J, N, E, T Noble Thermocouple: R, S, B |

| Accuracy: | RTD: – Class A [IEC 751] Thermocouple: Class 2 [ANSI MC 96.1] |

| Sensor details: | SS 316 Ø6 / Ø8 / Ø9.5 / Ø10 / Ø12 25mm up to 25000mm |

| Termination: | Extension & Compensating cables PTFE/PTFE or PTFE/PTFE/SS braded Others on request |

| Standard options: | Head mount transmitter [4 – 20mA] Cable glands & Blind plugs |

4. 8XXT / 8XXF / 8XXS / 8XXV / 8XXK Thermowells

| Type : | Threaded / Flanged / Sanitory Van-stone / Strakes Material: SS 304, SS 316, SS 316L, Monel Hastelloy C, Inconel, Super Duplex Titanium |

| Shank forms: | Straight / Tapered Reduced Tip / Partial Taper |

| Shank type: | Bar-stock / Pipe-fabricated |

| Standard options: | Material Test Certificate Wetted parts tested to NACE standards PFA lining / coating, Tantalum sleeves Stellite / Tungsten carbide coating |

Deiktis Technologies is a renowned pressure gauge, temperature gauge, thermocouple and RTD manufacturer based in Gujarat, India with international presence. You can buy pressure gauge, temperature gauge, RTD, thermocouple and thermowells manufactured with top-notch quality standards.

Download Catalogue and Datasheets

Catalogue

Catalogue - Catalogue (Updated)

Data-sheets

- 131B Utility Pressure Gauge - DOWNLOAD

- 131C Capsule Pressure Gauge / 232C Capsule Pressure Gauge - DOWNLOAD

- 132B Miniature Pressure Gauge / 142B Miniature Pressure Gauge / 134B Miniature Pressure Gauge / 144B Miniature Pressure Gauge - DOWNLOAD

- 133B Miniature Pressure Gauge - DOWNLOAD

- 233B Process Pressure Gauge / 234B Process Pressure Gauge / 235 Process Pressure Gauge / 236 Process Pressure Gauge - DOWNLOAD

- 253B Solid Front Pressure Gauge / 254B Solid Front Pressure Gauge / 263B Solid Front Pressure Gauge / 264B Solid Front Pressure Gauge - DOWNLOAD

- 532M Bimetal Process Temperature Gauge / 542M Bimetal Process Temperature Gauge - DOWNLOAD

- 611T Couple Inverted Diaphragm / 621T Couple Inverted Diaphragm / 631T Couple Inverted Diaphragm - DOWNLOAD

- 273B Phenolic Pressure Gauge / 274B Phenolic Pressure Gauge / 275 Phenolic Pressure Gauge / 276 Phenolic Pressure Gauge - DOWNLOAD

- 621F Flanged Inverted Diaphragm Seal / 641F Flanged Inverted Diaphragm Seal / 661F Flanged Inverted Diaphragm Seal - DOWNLOAD

- 622F Flanged Flushed Diaphragm Seal / 642F Flanged Flushed Diaphragm Seal / 662F Flanged Flushed Diaphragm Seal - DOWNLOAD

- 711R Transition Joint RTDS / 771R Transition Joint RTDS / 791R Transition Joint RTDS - DOWNLOAD

- 722R RTDS / 732R RTDS / 742R RTDS / 752R RTDS / 762R RTDS - DOWNLOAD