Jul 3, 2024

Welcome to this Deiktis Technologies blog! As we reflect on our journey and look ahead to the future, we are excited to share our story, products, and our future goals with you.

Our Story

Founded in 2018 in Vapi, Gujarat, Deiktis Technologies Private Limited emerged from a passion for innovation and a commitment to excellence in instrumentation. Our founders Syam, Ravi Kumar, and Ajay Patil, brought with them years of experience in engineering, maintenance, and plant operations, and a vision to create high-quality, reliable products that meet the evolving needs of various industries.

Our Products

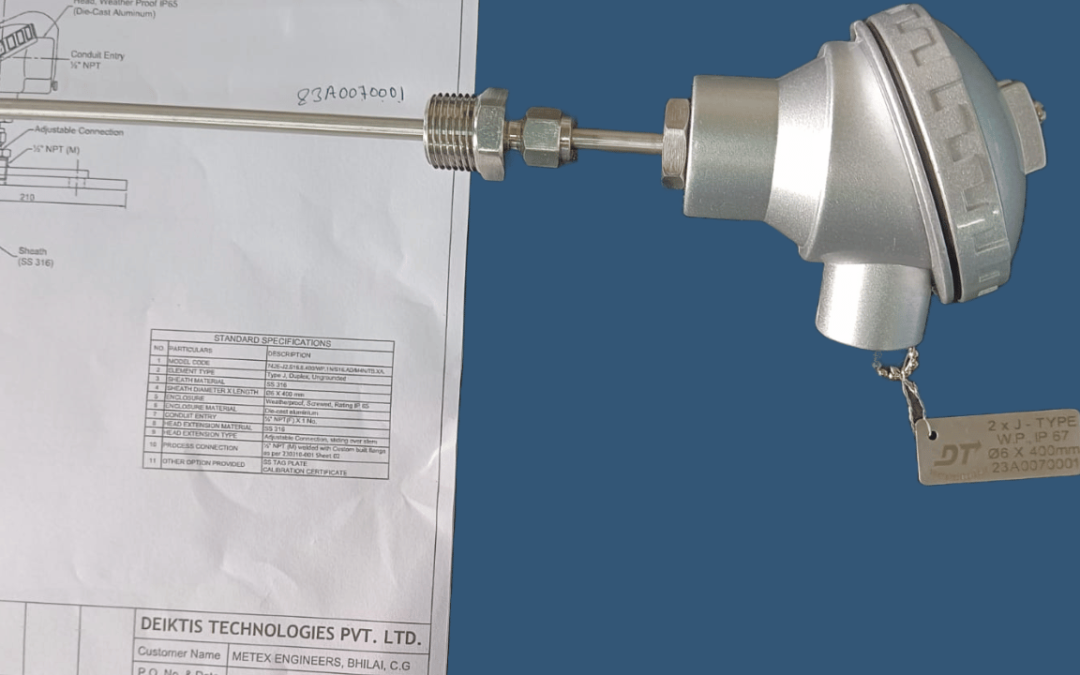

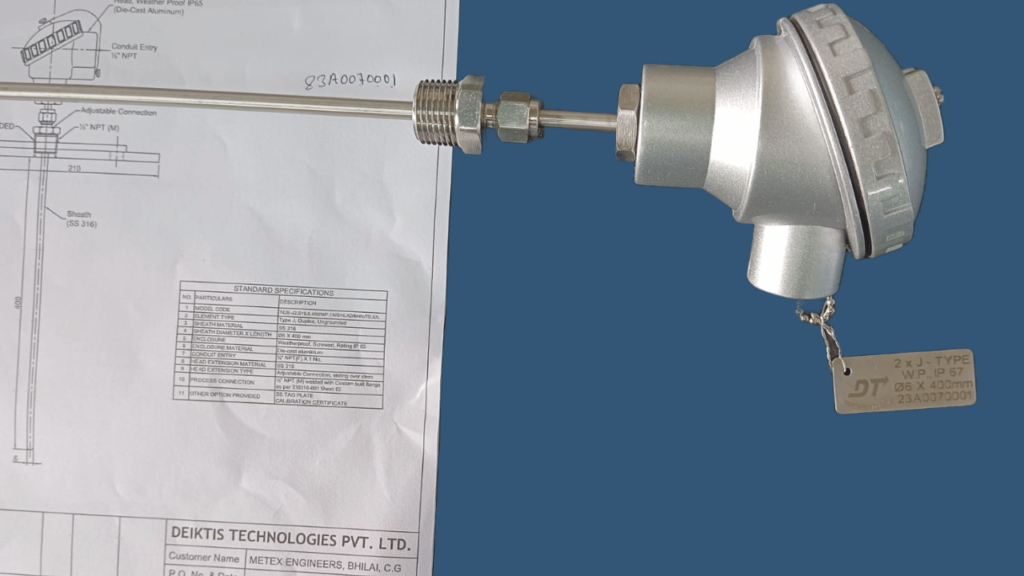

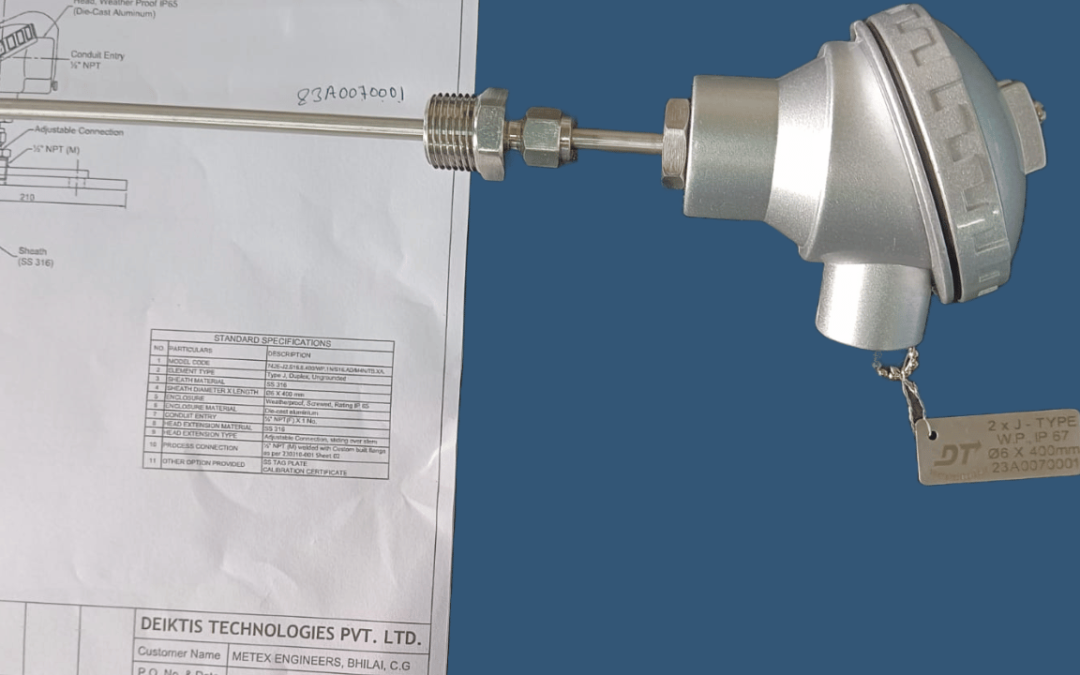

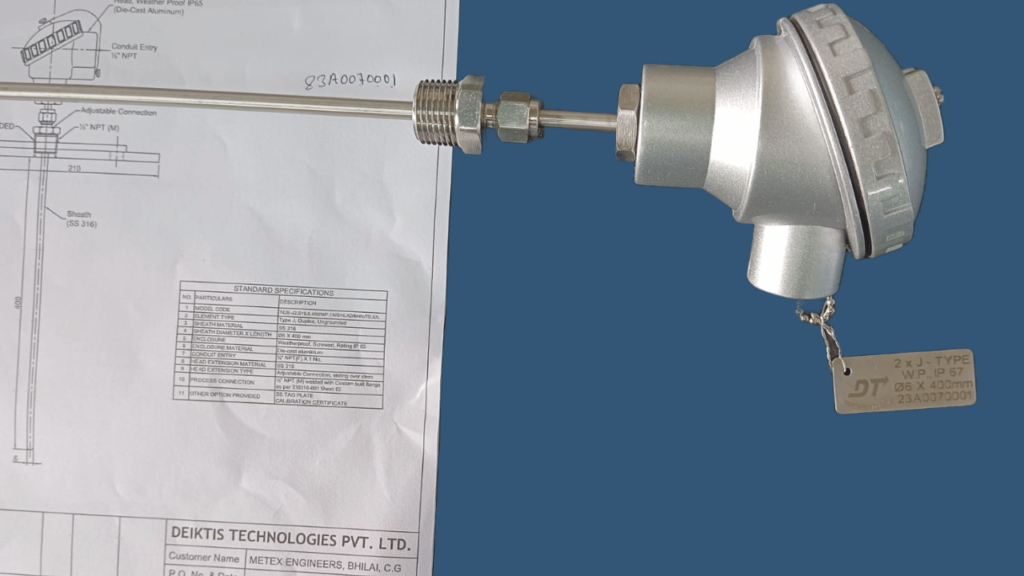

At Deiktis Technologies, we specialize in the manufacturing of Pressure/Temperature Gauges, RTDs, and Thermocouples. Our products are designed to provide accurate measurements, ensuring the highest levels of safety and efficiency in industrial operations. We take pride in our meticulous manufacturing processes and stringent quality control measures, which guarantee the durability and precision of our instruments.

Our Drive

Our drive is to deliver unparalleled instrumentation solutions that empower industries to achieve their operational goals with confidence. We are dedicated to continuous improvement, innovation, and customer satisfaction. By understanding the unique challenges faced by our clients, we strive to provide tailored solutions that exceed their expectations.

Our Future Goals

Looking forward, Deiktis Technologies envisions becoming a global leader in the instrumentation sector. We aim to expand our product range, enhance our technological capabilities, and enter new markets. Our commitment to sustainability and social responsibility guides our efforts to make a positive impact on the communities we serve.

Join Us on This Journey

We invite you to explore our website, learn more about our products, and connect with us. Whether you are a long-time customer or a new visitor, we value your interest and support. Stay tuned to our blog for updates on our latest developments, industry insights, and more.

Thank you for being a part of the Deiktis Technologies journey. Together, we are pioneering excellence in instrumentation. Indeed, we “measure with confidence”.

May 31, 2024

Introduction:

Gauge savers, also known as pressure gauge protectors, are essential components used to protect pressure gauges from exposure to excessive pressure, which can cause damage or inaccurate readings. They act as a safeguard to ensure the longevity and reliability of pressure gauges in various industrial applications.

What Are Gauge Savers?

Gauge savers are devices installed between the pressure gauge and the process to protect the gauge from pressure spikes or overloads. They typically consist of a spring-loaded mechanism that seals off the gauge when the pressure exceeds a predetermined limit, preventing the gauge from being exposed to damaging pressures.

How Do Gauge Savers Work?

Gauge savers operate on a simple but effective principle:

- Normal Operation: Under normal operating conditions, the gauge saver allows the process pressure to reach the gauge, enabling accurate pressure measurement.

- Overpressure Protection: When the pressure in the system exceeds the preset limit, the internal mechanism of the gauge saver activates. This mechanism usually involves a piston or diaphragm that moves to block the pressure pathway, isolating the gauge from the excessive pressure.

- Resetting: Once the pressure returns to a safe level, the gauge saver automatically resets, and the gauge resumes normal operation without any manual intervention.

Types of Gauge Savers:

There are various types of gauge savers designed to cater to different industrial needs. Some common types include:

- Spring-Loaded Gauge Savers: These are the most common type, using a spring mechanism to activate the protection. They are reliable and suitable for a wide range of applications.

- Diaphragm Gauge Savers: These use a diaphragm to isolate the gauge from overpressure. They are typically used in applications where the process media might be corrosive or viscous.

- Bellows-Type Gauge Savers: These are used for high-precision applications and provide accurate overpressure protection by using a bellows mechanism.

Applications of Gauge Savers:

Gauge savers are used in a variety of industries and applications, including:

- Oil and Gas: Protecting pressure gauges in drilling, refining, and pipeline monitoring systems.

- Chemical Processing: Safeguarding gauges from corrosive or hazardous chemicals.

- Water Treatment: Ensuring accurate pressure readings in filtration and distribution systems.

- HVAC Systems: Protecting gauges in heating, ventilation, and air conditioning systems.

- Manufacturing: Used in various manufacturing processes to protect gauges from pressure fluctuations.

Benefits of Using Gauge Savers:

- Extended Gauge Life: By protecting pressure gauges from overpressure, gauge savers help extend the operational life of the gauges, reducing the frequency of replacements.

- Enhanced Safety: Preventing gauge failure due to overpressure reduces the risk of accidents and equipment damage, ensuring a safer working environment.

- Cost Savings: Reducing the need for frequent gauge replacements and maintenance leads to cost savings over time.

- Accurate Readings: By protecting the gauge from pressure spikes, gauge savers help maintain the accuracy and reliability of pressure readings.

Conclusion:

Gauge savers are vital accessories for pressure gauges, providing essential protection against overpressure and ensuring accurate, reliable, and long-lasting performance. Incorporating gauge savers into pressure measurement systems enhances safety, reduces maintenance costs, and improves overall operational efficiency.

May 11, 2024

Understanding Thermocouples:

Thermocouples are widely used temperature sensors known for their simplicity, reliability, and wide temperature range. They operate based on the principle of the Seebeck effect, which states that a voltage is generated when two dissimilar metals are joined together and there is a temperature gradient between the junctions.

How Thermocouples Work:

A thermocouple consists of two different metal wires joined together at one end, known as the junction. When there’s a temperature difference between the junction and the other end of the wires (the cold junction), it creates a voltage proportional to the temperature difference. This voltage is then measured and correlated to the temperature using reference tables or equations specific to the type of thermocouple being used.

Types of Thermocouples:

There are various types of thermocouples, each with its own temperature range, accuracy, and characteristics. Some common types include:

- Type K: Made of Chromel (90% nickel, 10% chromium) and Alumel (95% nickel, 2% manganese, 2% aluminium, 1% silicon). Type K thermocouples are among the most commonly used due to their wide temperature range (-200°C to +1350°C), good accuracy, and relatively low cost.

- Type J: Composed of Iron and Constantan (55% copper, 45% nickel). Type J thermocouples have a more limited temperature range (-210°C to +1200°C) compared to Type K but offer good sensitivity and are suitable for use in vacuum or inert atmospheres.

- Type T: Made of Copper and Constantan. Type T thermocouples are known for their excellent accuracy and stability at low temperatures (-200°C to +350°C). They are often used in cryogenics and ultra-low temperature applications.

- Type E: Comprised of Chromel and Constantan. Type E thermocouples have a moderate temperature range (-270°C to +900°C) and high accuracy, making them suitable for a wide range of applications, including food industry and laboratory use.

- Type S, R, and B: These are noble metal thermocouples made of Platinum and Platinum-Rhodium alloys. They offer high accuracy and stability at high temperatures (up to +1800°C for Type S and R, and up to +1820°C for Type B) and are commonly used in industries like aerospace, automotive, and glass manufacturing.

Applications of Thermocouples:

Thermocouples find applications across various industries, including:

- HVAC systems for temperature control

- Industrial processes such as heat treating, forging, and welding

- Monitoring temperature in laboratories and research facilities

- Food industry for cooking and refrigeration processes

- Aerospace and automotive industries for engine monitoring

- Medical devices for patient monitoring and temperature measurement

Conclusion:

In conclusion, thermocouples are versatile temperature sensors that play a crucial role in temperature measurement and control across a wide range of applications and industries. Understanding their principles of operation, types, and applications can help in selecting the right thermocouple for specific temperature monitoring needs.

Apr 24, 2024

Introduction: In the realm of industrial measurements, precision and reliability are paramount. One crucial tool in achieving accurate temperature measurements is the Resistance Temperature Detector (RTD). In this blog post, we’ll delve into the basics of RTDs, exploring how they work and their significance in industrial applications.

What are RTDs? RTDs, or Resistance Temperature Detectors, are sensors used for measuring temperature by correlating the resistance of the RTD element with temperature. They operate on the principle that the resistance of certain materials changes predictably with temperature variations. This predictable change allows for precise temperature measurements across a wide range of industrial environments.

How do RTDs work? RTDs typically consist of a fine wire or film made from a material with a known and repeatable resistance-temperature relationship, such as platinum, nickel, or copper. Platinum RTDs are the most common due to their high accuracy and stability over a wide temperature range. As the temperature changes, the resistance of the RTD element changes predictably and linearly, allowing for precise temperature readings.

Industrial Applications of RTDs:

- Process Control: RTDs play a crucial role in industrial process control, where precise temperature monitoring is essential for maintaining product quality and optimizing manufacturing processes. Industries such as chemical processing, pharmaceuticals, and food and beverage rely on RTDs to ensure consistent temperatures during production.

- HVAC Systems: Heating, Ventilation, and Air Conditioning (HVAC) systems utilize RTDs for temperature sensing and control. RTDs help maintain comfortable indoor environments by accurately measuring air and water temperatures in heating and cooling systems.

- Automotive: In automotive applications, RTDs are used for engine temperature monitoring, ensuring optimal performance and preventing overheating. RTDs also play a role in climate control systems within vehicles, contributing to passenger comfort.

- Aerospace and Defense: In aerospace and defense applications, where extreme temperatures are common, RTDs are employed for precise temperature monitoring in engines, avionics, and other critical systems. Their reliability and accuracy make them indispensable for ensuring the safety and performance of aerospace and defense equipment.

Advantages of RTDs:

- High Accuracy: RTDs offer superior accuracy compared to other temperature sensing technologies, making them ideal for applications that require precise temperature measurements.

- Stability: RTDs exhibit excellent long-term stability, providing consistent and reliable temperature readings over time.

- Wide Temperature Range: RTDs can measure temperatures across a wide range, from cryogenic temperatures to high temperatures, making them versatile for various industrial applications.

Conclusion: Resistance Temperature Detectors (RTDs) are indispensable tools for precise temperature measurement in industrial settings. Their accuracy, stability, and wide temperature range make them ideal for a diverse range of applications, from process control to aerospace. Understanding the basics of RTDs and their significance in industrial measurements is essential for ensuring efficient and reliable operations across various industries.

Apr 16, 2024

When it comes to monitoring temperature, precision and reliability are paramount. Among the various types of temperature gauges available, bimetallic temperature gauges stand out for their unique design and robust functionality.

So, what exactly are bimetallic temperature gauges, and how do they work? Let’s delve into the fascinating world of temperature measurement.

Bimetallic temperature gauges operate on a simple yet ingenious principle. They consist of two different metal strips welded together, each with its own coefficient of thermal expansion. Typically, these metals are steel and brass or copper. As temperature changes, the two metals expand or contract at different rates, causing the strip to bend or coil. This bending motion is then transferred to a pointer or dial, which indicates the temperature on a scale. The greater the temperature change, the more the strip bends, providing a clear and accurate reading.

One of the key advantages of bimetallic temperature gauges is their durability and resilience. Since they rely on mechanical movement rather than electronic components, they are less prone to failure and can withstand harsh operating conditions. Moreover, bimetallic temperature gauges offer excellent accuracy across a wide temperature range, making them suitable for various applications, from industrial processes to HVAC systems and beyond. In addition to their reliability, bimetallic temperature gauges are also cost-effective and easy to install, making them a popular choice for many industries.

In conclusion, bimetallic temperature gauges represent a tried-and-tested solution for temperature monitoring, combining simplicity, accuracy, and durability. Whether you’re monitoring temperatures in a manufacturing plant or a commercial building, these reliable instruments are sure to deliver accurate results time and time again.

Stay tuned for more insights and updates on temperature gauges and other instrumentation technologies in future blog posts. Until then, keep exploring the world of measurement with Deiktis Technologies!

Apr 6, 2024

In the realm of process industries, understanding pressure measurement is paramount for ensuring optimal performance and safety. Pressure, the force exerted per unit area, is a fundamental parameter that directly influences various industrial processes. Let’s delve into the basics of pressure measurement, with a specific focus on pressure gauges, and essential tools for monitoring pressure levels in industrial environments.

Pressure measurement serves as a vital indicator of process conditions, aiding in the control and regulation of operations. Whether it’s monitoring fluid flow in pipelines, assessing vessel integrity, or optimizing equipment performance, accurate pressure measurement is indispensable.

Pressure gauges are instrumental devices utilized for measuring and displaying pressure levels within industrial systems. These gauges come in a variety of types, including Bourdon tube gauges, diaphragm gauges, and digital pressure gauges, each tailored to specific applications and pressure ranges.

Bourdon tube gauges, the most common type, operate on the principle of elastic deformation. When pressure is applied, the curved tube within the gauge straightens slightly, causing a pointer to move along a calibrated scale, indicating pressure readings.

Diaphragm gauges employ a flexible diaphragm that deflects in response to pressure changes, translating the deflection into pressure readings. These gauges are suitable for measuring low pressures and are often used in applications requiring high accuracy.

Digital pressure gauges, on the other hand, utilize electronic sensors to measure pressure and display readings digitally. These gauges offer advantages such as precise measurements, remote monitoring capabilities, and compatibility with digital communication protocols.

Regardless of the type, pressure gauges require proper installation, calibration, and maintenance to ensure accuracy and reliability. Regular calibration against known standards is essential to verify gauge accuracy and correct any deviations.

In conclusion, pressure measurement is a fundamental aspect of process industries, enabling effective monitoring and control of industrial processes. Pressure gauges play a pivotal role in this regard, providing real-time insights into pressure conditions within industrial systems. Understanding the basics of pressure measurement and selecting the appropriate gauge for each application is crucial for optimizing performance and ensuring operational safety in process industries.