Understanding Thermocouples:

Thermocouples are widely used temperature sensors known for their simplicity, reliability, and wide temperature range. They operate based on the principle of the Seebeck effect, which states that a voltage is generated when two dissimilar metals are joined together and there is a temperature gradient between the junctions.

How Thermocouples Work:

A thermocouple consists of two different metal wires joined together at one end, known as the junction. When there’s a temperature difference between the junction and the other end of the wires (the cold junction), it creates a voltage proportional to the temperature difference. This voltage is then measured and correlated to the temperature using reference tables or equations specific to the type of thermocouple being used.

Types of Thermocouples:

There are various types of thermocouples, each with its own temperature range, accuracy, and characteristics. Some common types include:

- Type K: Made of Chromel (90% nickel, 10% chromium) and Alumel (95% nickel, 2% manganese, 2% aluminium, 1% silicon). Type K thermocouples are among the most commonly used due to their wide temperature range (-200°C to +1350°C), good accuracy, and relatively low cost.

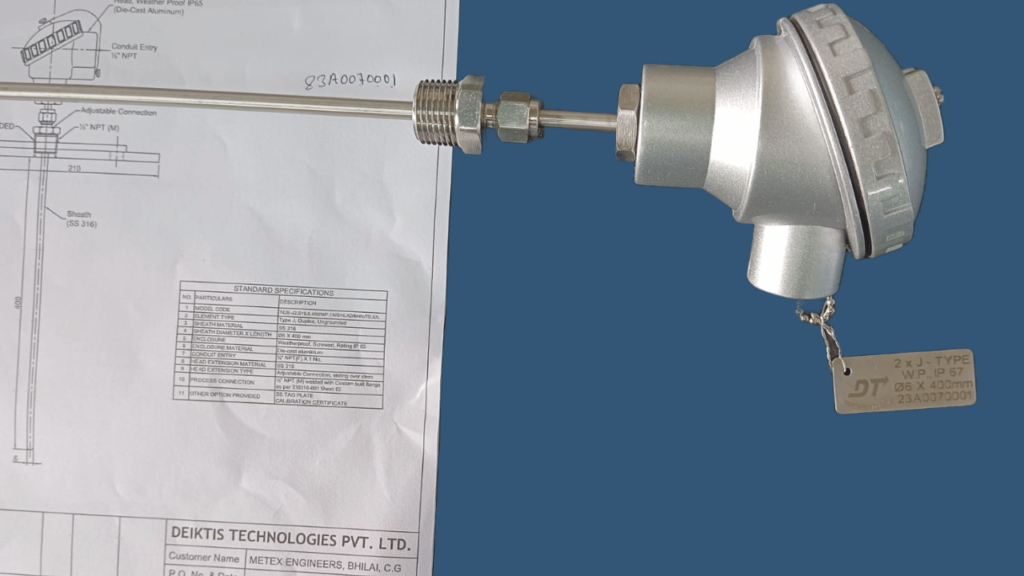

- Type J: Composed of Iron and Constantan (55% copper, 45% nickel). Type J thermocouples have a more limited temperature range (-210°C to +1200°C) compared to Type K but offer good sensitivity and are suitable for use in vacuum or inert atmospheres.

- Type T: Made of Copper and Constantan. Type T thermocouples are known for their excellent accuracy and stability at low temperatures (-200°C to +350°C). They are often used in cryogenics and ultra-low temperature applications.

- Type E: Comprised of Chromel and Constantan. Type E thermocouples have a moderate temperature range (-270°C to +900°C) and high accuracy, making them suitable for a wide range of applications, including food industry and laboratory use.

- Type S, R, and B: These are noble metal thermocouples made of Platinum and Platinum-Rhodium alloys. They offer high accuracy and stability at high temperatures (up to +1800°C for Type S and R, and up to +1820°C for Type B) and are commonly used in industries like aerospace, automotive, and glass manufacturing.

Applications of Thermocouples:

Thermocouples find applications across various industries, including:

- HVAC systems for temperature control

- Industrial processes such as heat treating, forging, and welding

- Monitoring temperature in laboratories and research facilities

- Food industry for cooking and refrigeration processes

- Aerospace and automotive industries for engine monitoring

- Medical devices for patient monitoring and temperature measurement

Conclusion:

In conclusion, thermocouples are versatile temperature sensors that play a crucial role in temperature measurement and control across a wide range of applications and industries. Understanding their principles of operation, types, and applications can help in selecting the right thermocouple for specific temperature monitoring needs.